Machine BZ 300/PTN: versatility and precision for every material

The hot stamping machine BZ 300/PTN, designed and manufactured by Bizeta, is the ideal solution for the hot transfer of logos and labels sharp and durable.

It offers precise prints on a wide range of both soft and rigid materials, ranging from leather to plastic, paper, cardboard and wood, also allowing you to add special effects comparable to a metallic finish, and thus play with a rich color palette.

Thank to its versatility, the machine allows to carry out different hot stamping techniques with a high precision result.

Main stamping techniques of the BZ 300/PTN

- Stamping starting from foil: this process occurs through a cliché engraved with the graphics to be transferred, heated to the correct temperature and combined with the pressure exerted by the press. ideal for plastic and non-plastic materials.

- Stamping from a transfer tape: the graphics is previously made on a transfer tape and then heat- transferred onto the desired material using a silicone pad attached to the heated cliché. an integrated optical fiber precisely reads the reference marks on the tape, ensuring maximum accuracy.

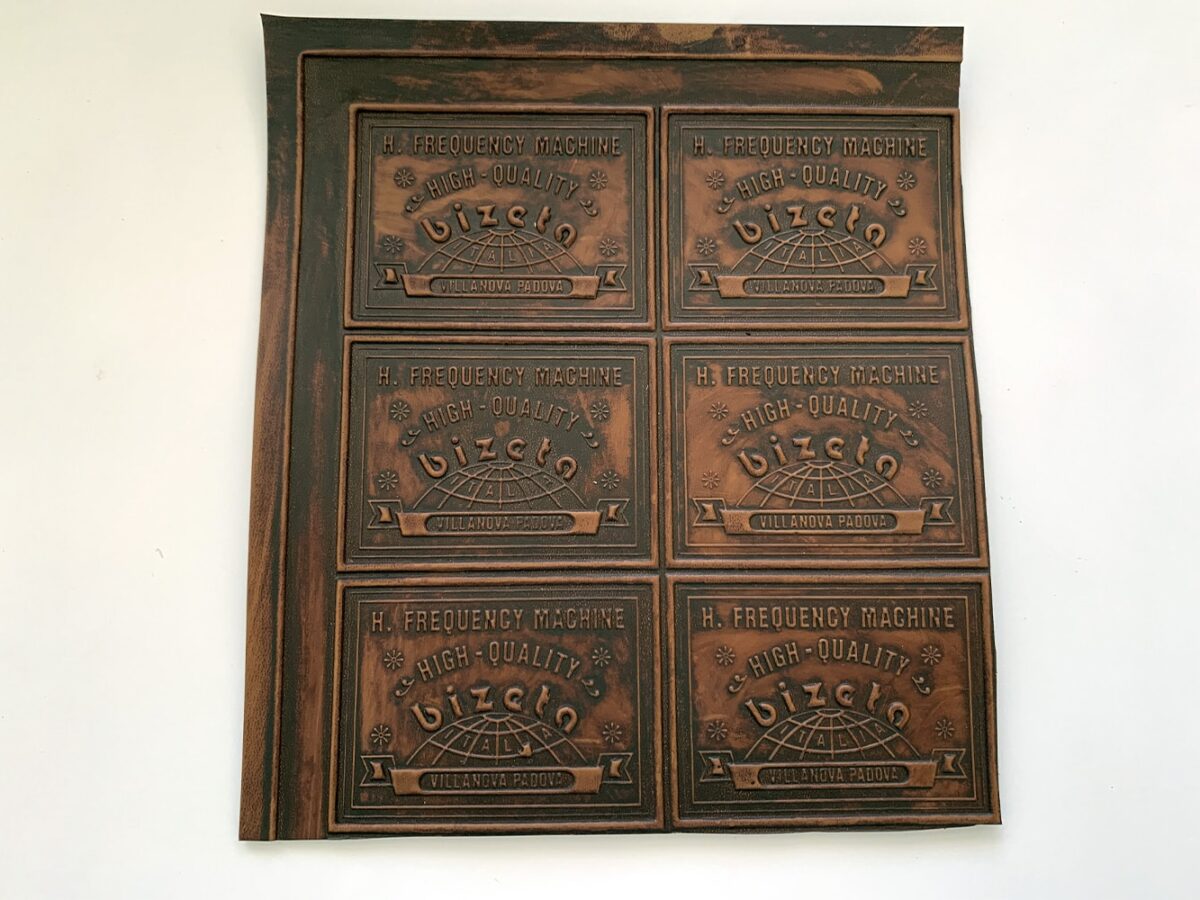

- Marking of leather and wood: perfect for customizing of leather, “simil” leather, cardoboard or wood, this technique uses an engraved cliché to create the effect of “fire burn” on the material.

The BZ 300/PTN machine can be integrated with a rotative table and a system for an automatic loading and unloading, which significantly increase productivity, making the machine ideal even for large-scale productions.

Integrable rotative table

Mould temperature up to 400°c

Cliché dimensions from 60 x 100 mm to 300 x 350 mm

Who is the hot stamping machine BZ 300/PTN for?

The BZ 300/PTN is a hot stamping machine indicated for companies working for:

- Luxury leather industry;

- gift-packaging and cosmetic labels industry;

- textile;

- stationery.

Would you like to receive more information about this hot stamping press?

High-quality workmanship and customized finishing of leathers, synthetic materials and fabrics for high fashion thanks to bizeta high frequency

All the high frequency welding and blanking machines in bizeta respect the standards of “industry 4.0”, through the interconnection to the company it systems, data exchange between company management system and machine, the possibility of planning, management and continuous monitoring of the work process and remote assistance with diagnosis and maintenance.

High frequency welding and blanking machines are equipped with siemens hmi and components for an intuitive and simple interface for the operator.

The technology offers the possibility of creating countless receipts of working cycles, saving the parameters for each.

This allows to optimize the production process times retrieving the parameters, already saved, every time a mould change is done by the operator.

Bizeta hf machines can be equipped with a function that allows the operator to adjust the mould pressure on the material during the work cycle.

This pressure is shown and can be adjusted using the hmi console panel.

Here in bizeta we carry out all the operations of maintenance, ordinary and extraordinary, directly in our client’s companies with quick turnaround times.

We also guarantee eventual mechanic and electrical repairs by our specialized and constantly updated technicians.