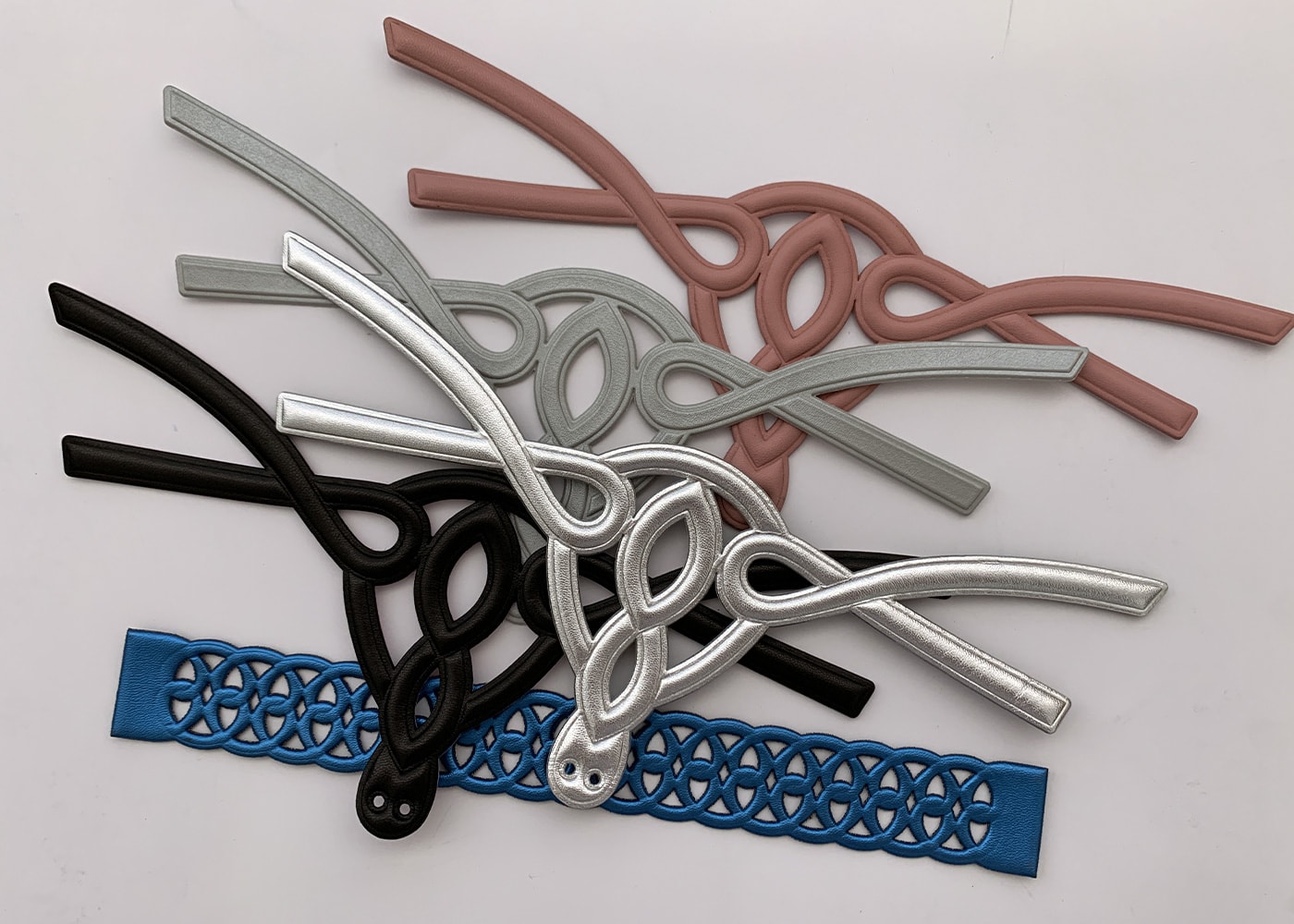

High frequency welding and blanking machine is composed of two units: the first one is to weld while the second one is to blank on PVC materials, PU, polyester and coupled leather. It can work with screen-printed sheets, thanks to its high precision on positioning of the rotating table.

Aluminium, brass or photoengrave magnesium electrodes and/or mould are used to high frequency weld, while tempered and ground hand punches are used to blank.

Each station of the rotating table is equipped with a tempered and ground steel plate that allows all working process without interposing any other kind of material between cliché or hand punch and the working-plane.

The machine is equipped with a touch screen to program the working cycle, automatic adjustment of the welding force, lighted cross lasers to place sheets, a high sensibility anti-discharge circuit and a mould holder designed for the connection to the cooling circuit.

Technical features

| BZ 1230T |

BZ 2550T |

BZ 2550ST |

||

| Max welding force WELDING | Kg | 2000 | 6000 | 6000 |

| Max power efficiency at the electrodes WELDING | kW | 10 | 30 | 30 |

| Max BLANKING force WELDING | Kg | 30000 | 60000 | – |

| Max welding force WELDING-BLANKING | Kg | – | – | 50000 |

| Max blanking force WELDING-BLANKING | Kg | – | – | 60000 |

| Max power efficiency at the electrodes WELDING-BLANKING | kW | – | – | 30 |

| Number of station of the rotating table | n. | 4 | 4 | 4 |

| Electrodes-holder plate dimensions | mm | 400 x 470 | 480 x 700 | 480 x 700 |

The above-mentioned aesthetic and technical specifications are not binding. Our company reserves itself the right to introduce, without any notice, any changes in order to improve the working and the output of the machine.